As previously washed the windows in the Empire State Building skyscraper

Along with the appearance in New York of the tallest buildings in the world, the question arose of washing windows. After all, it is one thing to wash the windows in your apartment, and quite another - in a 50 or even 100-story building, in which there are thousands of them. And they need to be washed much more often than we are used to doing at home.

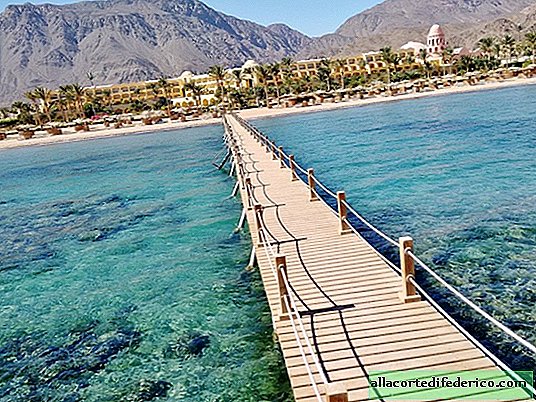

Window Cleaner of the Empire State Building, 1936

Window Cleaner of the Empire State Building, 1936In the world-famous New York skyscraper Empire State Building, there was a special unit in which eight people worked on a regular basis. All of them were responsible for the cleanliness of 6514 windows of the highest building at that time in the world. According to the norm adopted by the management company, each window had to be washed inside and out at least once every two weeks. Some windows during this time were polluted more than others, some less, but all had to be washed without exception. In addition, the grandiose office building, the view from the windows of which was one of the main competitive advantages, could not allow dirty stains and smudges to interfere with this beautiful view.

The washers were divided into deuces, each of which was responsible for 25 floors. That deuce who finished her work front first got the right to wash the top floors and some free time on the observation deck of a skyscraper. Couples were needed so that the workers looked after each other and could come to the aid of a comrade in case of something. Due to the increased danger, it was forbidden to work during very strong winds, in rain or snow, although the workers themselves considered the rain the best time to wash, as everything was easier to wipe and there was no need to carry a lot of water with them. In anticipation of good weather, the workers entertained themselves with card games in the locker room.

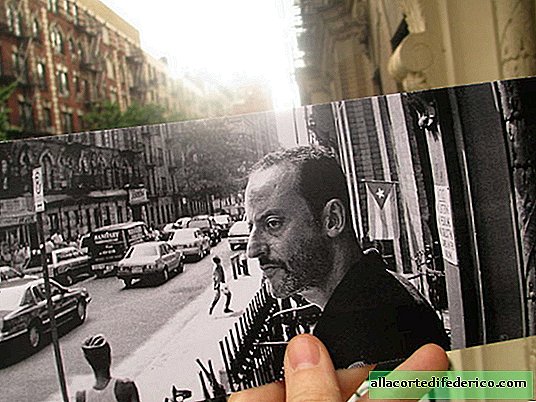

The window, regardless of floor, was washed as follows. First inside. And here everything is simple, since everyone, as it seems to me, did this at least once in a lifetime. Difficulties began further. The washer opened the bottom flap, crawled out (on the 80th, for example, floor), clung a thick leather belt to a special hook on the outside of the frame, closed the window, hooked a second belt on the second hook and stood up resting on the windowsill, whose width was only 4 cm. After that, he began washing the outer surface. Despite the primitiveness, the design was quite reliable and held the person even when one of the belts was broken.

Illustration from Modern Mechanix magazine for September 1934.

The most dangerous thing was in winter, when outside the window were freezing temperatures and a piercing icy wind was blowing. Frames often wedged, and window sills and windows outside were covered with a layer of ice and snow. If for some reason the worker could not open the window from the outside, his companion from the deuce or one of the office workers who were indoors came to his aid. If there was no one to help the poor fellow stuck at a height, then the only way out was to break the glass with his foot.

A rag in your pocket, suede for wiping on a belt around your neck, a washcloth in a bucket and a copper scraper with an elastic band fastened with a chain to your belt. The bucket was left inside so that, God forbid, it would fall on someone’s head. For the same reason, you could not use brushes. For washing used only soapy water. No ammonia or miraculous cleaning products that are so popular today. It took four minutes to wash one window. Three, if in a hurry. Then back to the room and repeat again. And so from morning to evening every day with interruptions in bad weather. Each worker had to wash 75 windows a day. One of the drawbacks of this technology was that the washer, with his work and his presence, paralyzed the office for some time. Someone was simply distracted by an outsider, someone was curious to look at the man hanging outside the window, and someone had to free up his seat at the window so that the washer could get out.

In 1934, the head of the team of washers of the Empire State Building, Richard Hart, in an interview with the American magazine Modern Mechanix, spoke about his 65-year-old employee, who had been working only with windows all his life and finally decided to retire. A day later, he asked again, saying that he really lacked the dizzying heights and breathtaking views that he was used to. "Over the years, heights have been absorbed into your blood," Hart said, "and you will never be able to work on earth." The work of the washers was considered quite prestigious and paid well. According to Hart, the average washer income was $ 30 a week, or $ 1,560 a year. This was more than a factory worker ($ 430 a year) or an ordinary builder ($ 907 a year) received, and roughly equal the income of a qualified electrician ($ 1,559 a year). But there was no need to have an education, and work, unlike a factory or factory, was much easier, took place in the fresh air and with good views. Of the minuses, there was a risk of falling down, as well as difficulties with insurance. Most insurance companies rated their work as incredibly risky and refused to sell the policy. In those years, about 3,000 window washers worked in New York, and despite the fact that about 10 people died every year, there was no shortage of people wishing to learn a new profession.

In the 50s of the last century, with the advent of fully glazed facades, the washing technology changed and the leather belt with hooks was replaced by suspended cradles and mechanical scaffolding. Today, hooks on frames can be found only in some houses of the pre-war building, where they have been preserved and are sometimes still used.

During the reconstruction of the Empire State Building, all windows were replaced with the so-called swing-in. And this is a pretty convenient design when it comes to washing. These windows fold in and you don’t have to get out and risk your life to wash them.

The only but significant minus in all this is time. To deal with them in four minutes will not work for sure. Now the cleanliness of the windows of the Empire State Building is watched by only 4 people. It takes about 2 months to wash all the windows in the building, after which they start all over again.